Lamp beads

Usually, 1W LED lamp beads are used for power greater than 30W, and low-power LED lamp beads (such as 3020, 3014, 3528, etc.) are mostly used for those with power less than 30W. It is recommended to use SMD low-power LEDs to facilitate heat dissipation and improve the uniformity of light emission. The lamp beads can be arranged according to their shape. For example, if the shape is round, then the lamp beads are arranged in a circle. On the contrary, if the shape is square, then they are arranged in a square.

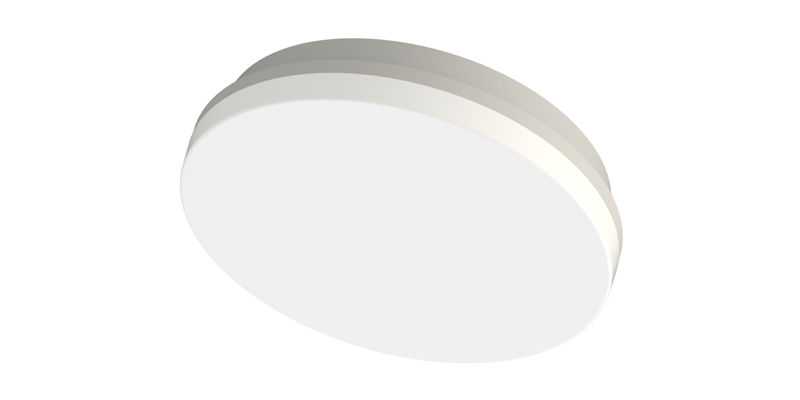

There are two circles of LED lamp beads on the circular printed board. It uses 23 0.4W type 5730 LED lamp beads, with a total power of 18W. The rectangle in the middle is the constant current power supply, and the lower right corner of the box is the photodiode of the remote control receiver to receive the infrared control signal of the remote control brightness.

What needs to be mentioned is that there are still a large number of low-cost LED ceiling lamps that use low-power straw hat lamps. However, due to the large thermal resistance of straw hat lamps (450℃/W), it is difficult to dissipate heat, so the light decay is serious and the life is very short. .

Lampshade

The lampshade usually adopts PC board, and its performance is as follows:

(1) Light transmittance: The light transmittance of PC board can reach up to 89%, which can be as beautiful as glass. The UV coated board will not produce yellowing, fogging and poor light transmission under the sun. The loss of light transmission after ten years is only 6%, the loss rate of PVC is as high as 15%-20%, and the loss rate of glass fiber is 12%. %-20%.

(2) Impact resistance: The impact strength of PC board is 250-300 times that of ordinary glass, 30 times that of acrylic plate of the same thickness, and 2-20 times that of tempered glass. There is no crack when dropped from two meters below a 3kg hammer. Unbreakable Glass" and "Sound Steel".

(3) Anti-ultraviolet: One side of the PC board is coated with anti-ultraviolet (UV) coating, and the other side has anti-condensation treatment, which integrates the functions of anti-ultraviolet, heat insulation and anti-drip. It blocks UV rays from passing through and is suitable for protecting valuable artwork and exhibits from UV damage.

(4) Light weight: the specific gravity is only half of that of glass, saving the cost of transportation, handling, installation and supporting the frame.

(5) Flame retardant: The national standard GB50222-95 confirms that the PC board is a flame retardant grade 1, that is, B1 grade. The PC board's own ignition point is 580 degrees Celsius, and it will self-extinguish after leaving the fire. No toxic gas will be produced when burning, and it will not contribute to the spread of the fire.

(6) Bendability: According to the design drawing, the cold bending method can be adopted on the construction site, and it can be installed in the shape of an arch, a semi-circular top and a window. The minimum bending radius is 175 times the thickness of the plate, and it can also be hot bent.

(7) Temperature adaptability: PC board does not become cold and brittle at -100 °C, does not soften at 135 °C, and its mechanics and mechanical properties have no obvious changes in harsh environments.

(8) Weather resistance: PC board can maintain the stability of various physical indicators in the range of -40°C to 120°C. After 4000 hours of artificial weathering test, the yellowing degree is 2, and the light transmittance reduction value is only 0.6%.